Vontron Reverse Osmosis Membrane ULP21-4040

- Regular price

- R 2,499.99

- Regular price

-

- Sale price

- R 2,499.99

- Unit price

- per

Vendor : puritechwater

Product Type :

Sku : ULP21-4040

Couldn't load pickup availability

ULP series of ultra-low pressure aromatic polyamide compound membrane element newly developed by Vontron Membrane Technology Co., Ltd. can work under ultra low pressure to reach as high permeate flow and rejection same as regular low-pressure membrane element, and is applicable to desalination of surface water and underground water.

--

VONTRON MEMBRANE

Who is Vontron? What can RO membrane do?

https://youtu.be/PzS7Y6fgFUs

Installing A 4040 Vontron Membrane

https://youtu.be/_ORPqr1olRw

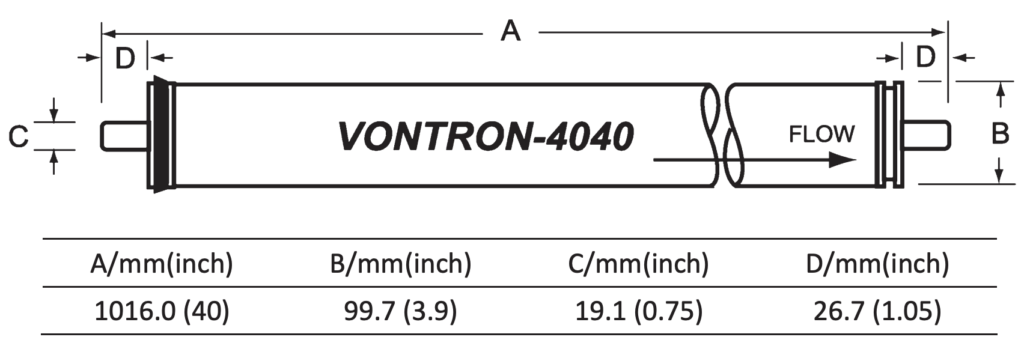

Dimensions Of A 4040 Membrane

4" LP Series Of Low Pressure RO Element

The LP (low pressure) series of aromatic polyamide compound membrane elements developed by Vontron Technology Co., Ltd. has the properties of low-pressure operation, high permeate flow, and excellent desalination and is applicable to the desalination of brackish water. Besides, it is particularly applicable to the fabrication of high-purity water for the electronic industry and electric power industry owing to its excellent performance in removing soluble salts, TOC, SiO2, etc. Being suitable for desalting such water sources as surface water, underground water, tap water, and municipal water, etc., the LP series is mainly applicable to the treatment of various industrial water such as industrial-purpose pure water, boiler water replenishment in power plants, and can be also applied to such brackish water applications, such as treatment of high-concentration saline wastewater and production of beverage-purpose water.

LP series of the low-pressure elements is normally suitable for the treatment of brackish water, surface water, underground water, and municipality water with TDS that is less than 10000ppm. It is mainly used for producing various scales of bottle water, drinking water, industrial used pure water, high purity water, boiler replenishment water, also for wastewater reuse, material concentration, purification, and refining purposes.

- Testing Conditions

- Testing Pressure: 225 psi (1.55Mpa)

- The temperature of Testing Solution: 25 °C

- The concentration of Testing Solution (NaCl): 2000ppm

- pH Value of Testing Solution: 7.5

- Recovery Rate of Single Membrane Element: 15%

- Operation Limits & Conditions

- Max. Working Pressure: 600psi (4.14Mpa)

- Max. Feedwater Flow: 75gpm (17 m3/h) (for 8040) | 16gpm (3.6 m3/h) (for 4040)

- Max. Feedwater Temperature: 45 °C

- Max. Feedwater SDI: 5

- Residual chlorine Concentration of Feedwater: <0.1ppm

- pH Range of Feedwater during Continuous Operation: 3~10

- pH Range of Feedwater during Chemical Cleaning: 2~12

- Max. Pressure Drop of Single Membrane Element: 15psi (0.1Mpa)

Major Properties Of 4" LP Element

| Model | Active Membrane Area ft2(m2) | Spacer Thickness mil | Permeate Flow GPD(m3/d) | Stable Rejection Rate % | Minimun Rejection Rate & |

| LP100 | 100 (9.3) | 28 | 2500 (9.4) | 99.7 | 99.5 |

| LP11-4040 | 90 (8.4) | 28 | 3000 (11.4) | 99.3 | 99.0 |

| LP21-4040 | 100 (8.4) | 28 | 2400 (9.1) | 99.5 | 99.3 |

Note: The permeate flow listed in the table is the average value. The permeate flow of single element is tolerance to ±15% of this value.

4" ULP Series Of Ultra Low Pressure RO Element

The ULP (ultra-low pressure) series of aromatic polyamide compound membrane elements developed by Vontron Technology Co., Ltd for the treatment of surface water and underground water. Its operation is about 2/3 of the low-pressure membrane, and the rejection rate can reach 99%. Thus it can reduce the investment cost of related pumps, pipelines, containers, and other equipment and operation costs of reverse osmosis system, and improve economic benefits.

ULP RO element is normally suitable for the treatment of brackish water, surface water, underground water, and municipality water with TDS that is less than 2000ppm. It is mainly used for producing various scales of bottle water, drinking water, boiler replenishment water, food processing, and pharmaceutical manufacturing industries, and other fields.

- Testing Conditions

- Testing Pressure: 150 psi (1.03Mpa)

- The temperature of Testing Solution: 25 °C

- The concentration of Testing Solution (NaCl): 1500ppm

- pH Value of Testing Solution: 7.0±0.5

- Recovery Rate of Single Membrane Element: 15%

- Operation Limits & Conditions

- Max. Working Pressure: 600psi (4.14Mpa)

- Max. Feedwater Flow: 75gpm (17 m3/h) (for 8040) | 16gpm (3.6 m3/h) (for 4040)

- Max. Feedwater Temperature: 45 °C

- Max. Feedwater SDI: 5

- Residual chlorine Concentration of Feedwater: <0.1ppm

- pH Range of Feedwater during Continuous Operation: 3~10

- pH Range of Feedwater during Chemical Cleaning: 2~12

- Max. Pressure Drop of Single Membrane Element: 15psi (0.1Mpa)

Major Properties Of 4" LP Element

| Model | Active Membrane Area ft2(m2) | Spacer Thickness mil | Permeate Flow GPD(m3/d) | Stable Rejection Rate % | Minimun Rejection Rate & |

| LP100 | 100 (9.3) | 28 | 2800 (10.6) | 99.5 | 99.2 |

| ULP11-4040 | 90 (8.4) | 28 | 2400 (9.1) | 99.0 | 98.5 |

| ULP21-4040 | 90 (8.4) | 28 | 1900 (7.2) | 99.4 | 99.0 |

Note: The permeate flow listed in the table is the average value. The permeate flow of single element is tolerance to ±20% of this value.

Important Information

- Any specific application must be limited within the Operating Limits and Conditions. We strongly recommend you to refer to the latest edition of the technology manual and design guide prepared by Vontron Technology Co., Ltd., or consult experts proficient in membrane technology. In case the customer fails to follow the operating conditions as specified in this manual, Vontron Technology Co., Ltd. will assume no liability for all results.

2. The permeate flow listed in the table is the average value. The permeate flow of a single membrane element is within a tolerance not exceeding ±20% of the nominal value.

3. All wet-type membrane elements have been strictly tested before leaving the factory, and have been treated with the solution of 1.0% sodium hydrogen sulfite (an antifreeze solution of 10% propanetriol required in winter) for storage purpose, then sealed with a plastic bag in a vacuum, and further packed in carton boxes. In order to prevent the breeding of microbes during short-time storage, transportation, and system standby, we recommend you soak the membrane elements with the protective solution (prepared with RO filtered water) containing 1.0% sodium hydrogen sulfite

(foodstuff-purpose).

4. Discard the RO-filtered water produced during the first one hour after system start-up.

5. During storage time and run time, it is strictly prohibited to dose any chemical medicament that may be harmful to membrane elements. In case of any violation in using this kind of chemical medicament, Vontron Technology Co., Ltd. assumes no liability for any outcome incurred therefrom.

Points of Attention

1. All data and information provided in this manual have been obtained from a long-term experiment by Vontron Technology Co., Ltd. We confirm that these data and information are accurate and effective. Vontron Technology CO., Ltd. assumes no liability for any aftermath caused by the user’s failure in abiding by the conditions specified in this manual in use or maintenance of membrane products. It is strongly recommended that the user shall strictly abide by the requirements for the design, use, and maintenance of products and keep relevant records.

2. Along with technical development and product renovation, the information contained herein will be subject to modification without prior notification. Please visit the website of Vontron Technology Co., Ltd. for any update of the product.